-

tel:

+86 133 9419 1191 -

email:

faygo2028@gmail.com

Aseptic filling lines

Aseptic filling lines

The aseptic filling line is a complete, integrated production system designed to package beverages in a sterile environment, ensuring product safety and longevity without refrigeration. Unlike traditional hot-fill systems, this technology separately sterilizes the product and the packaging material before bringing them together in a sterile chamber. For beverage producers, this process is the ultimate solution for achieving a long, clean-label shelf life—often exceeding 12 months—while preserving the fresh taste, color, and nutritional value of sensitive products.

.webp?x-oss-process=image/resize,w_100/quality,q_100)

.webp?x-oss-process=image/resize,w_100/quality,q_100)

.webp?x-oss-process=image/resize,w_100/quality,q_100)

.webp?x-oss-process=image/resize,w_100/quality,q_100)

.webp?x-oss-process=image/resize,w_100/quality,q_100)

.webp?x-oss-process=image/resize,w_100/quality,q_100)

.webp?x-oss-process=image/resize,w_100/quality,q_100)

.webp?x-oss-process=image/resize,w_100/quality,q_100)

.webp?x-oss-process=image/resize,w_100/quality,q_100)

.webp?x-oss-process=image/resize,w_100/quality,q_100)

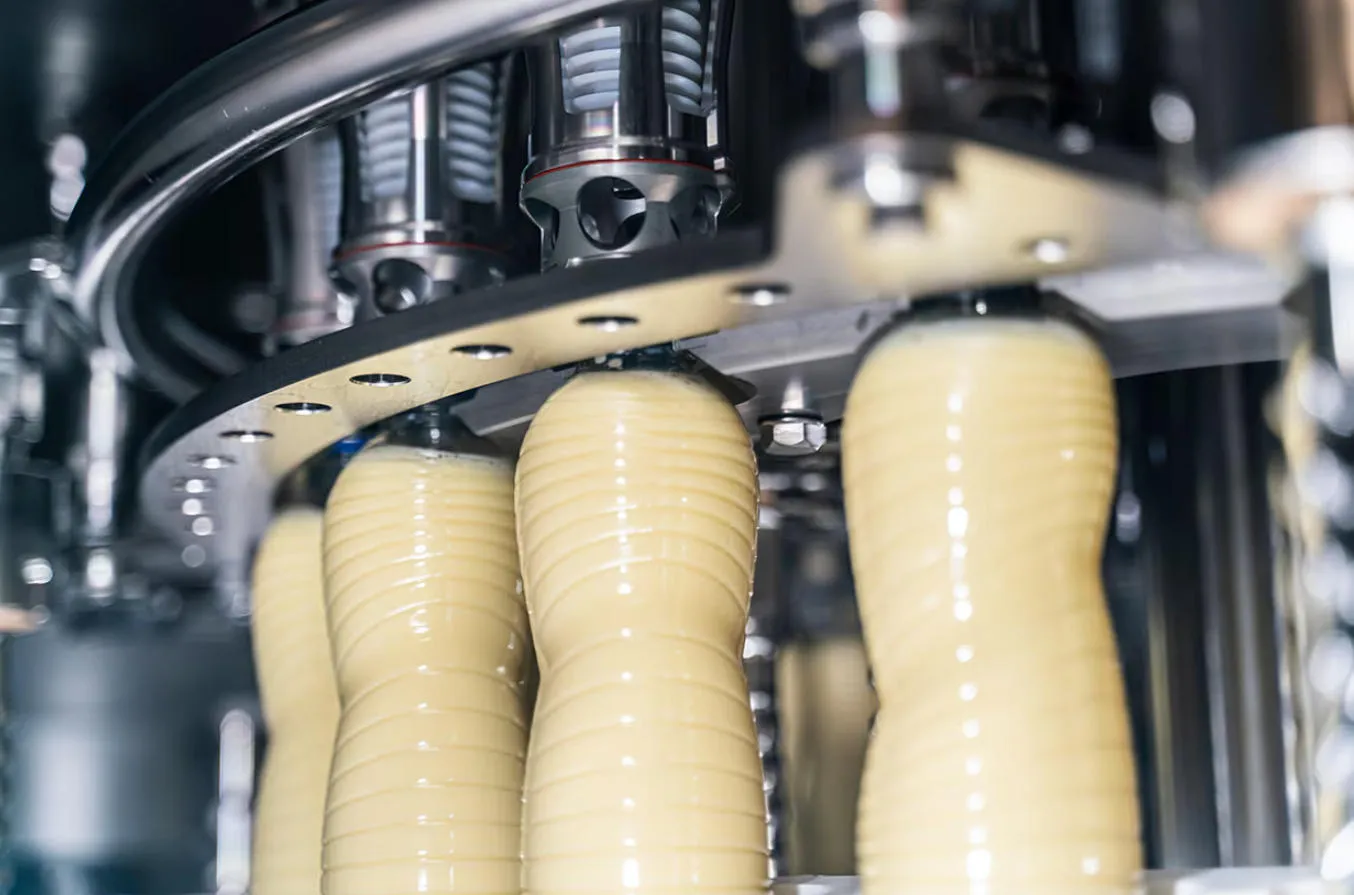

The system operates on the principle of maintaining sterility throughout the entire packaging process. The product is first sterilized, typically using an Ultra-High Temperature (UHT) or High-Temperature Short-Time (HTST) process, which heats the liquid to a high temperature for a few seconds and then rapidly cools it. This step effectively eliminates all microorganisms without significantly damaging the product's quality. Simultaneously, the packaging materials—preforms or bottles—are sterilized using methods like hydrogen peroxide (H₂O₂) vapor, peracetic acid, or intense UV light. The sterile product and sterile containers then meet inside a sterile, positive-pressure chamber where the filling and capping take place, preventing any recontamination from the outside environment.

Aseptic filling lines are engineered for high-output, continuous production, offering remarkable flexibility to suit different business scales and product portfolios.

- Production Output: The capacity of an aseptic line is highly adaptable to the specific bottle type and size. For smaller, single-serve bottles (e.g., 200ml to 500ml), modern high-speed aseptic lines can achieve outputs of up to 36,000 bottles per hour (BPH). For larger bottle formats (e.g., 1-liter family sizes), the production speed is accordingly robust, typically ranging from 3,000 to 12,000 BPH. This scalability allows manufacturers to select a system that perfectly matches their production volume and container requirements.

- Compatible Products: This advanced technology is ideal for a wide range of low-acid and high-acid beverages that are sensitive to heat or oxygen.

- Dairy and Plant-Based Milk: Such as fresh milk, cream, soy milk, and almond milk.

- Juices and Nectars: Especially those that are heat-sensitive and benefit from a fresh taste.

- Liquid Nutritional Drinks and Protein Shakes.

- Still Beverages and Ready-to-Drink (RTD) Teas and Coffees.

By ensuring that the product and package are sterilized separately and combined in a contaminant-free environment, an aseptic filling line offers unparalleled product quality and safety. It is a strategic investment for brands aiming to enter new markets, extend product distribution, and meet consumer demand for natural, preservative-free beverages with a superior flavor profile.

.webp?x-oss-process=image/resize)

.webp?x-oss-process=image/resize)

.webp?x-oss-process=image/resize)

.webp?x-oss-process=image/resize)

.webp?x-oss-process=image/resize)

.webp?x-oss-process=image/resize)

.webp?x-oss-process=image/resize)

.webp?x-oss-process=image/resize)

.webp?x-oss-process=image/resize)

.webp?x-oss-process=image/resize)

.webp)

.webp?x-oss-process=image/resize,w_100/quality,q_100)

.webp?x-oss-process=image/resize,w_100/quality,q_100)

.webp?x-oss-process=image/resize,w_100/quality,q_100)

.webp?x-oss-process=image/resize,w_100/quality,q_100)