-

tel:

+86 133 9419 1191 -

email:

faygo2028@gmail.com

ABS Pipe Extrusion Line

ABS Pipe Extrusion Line

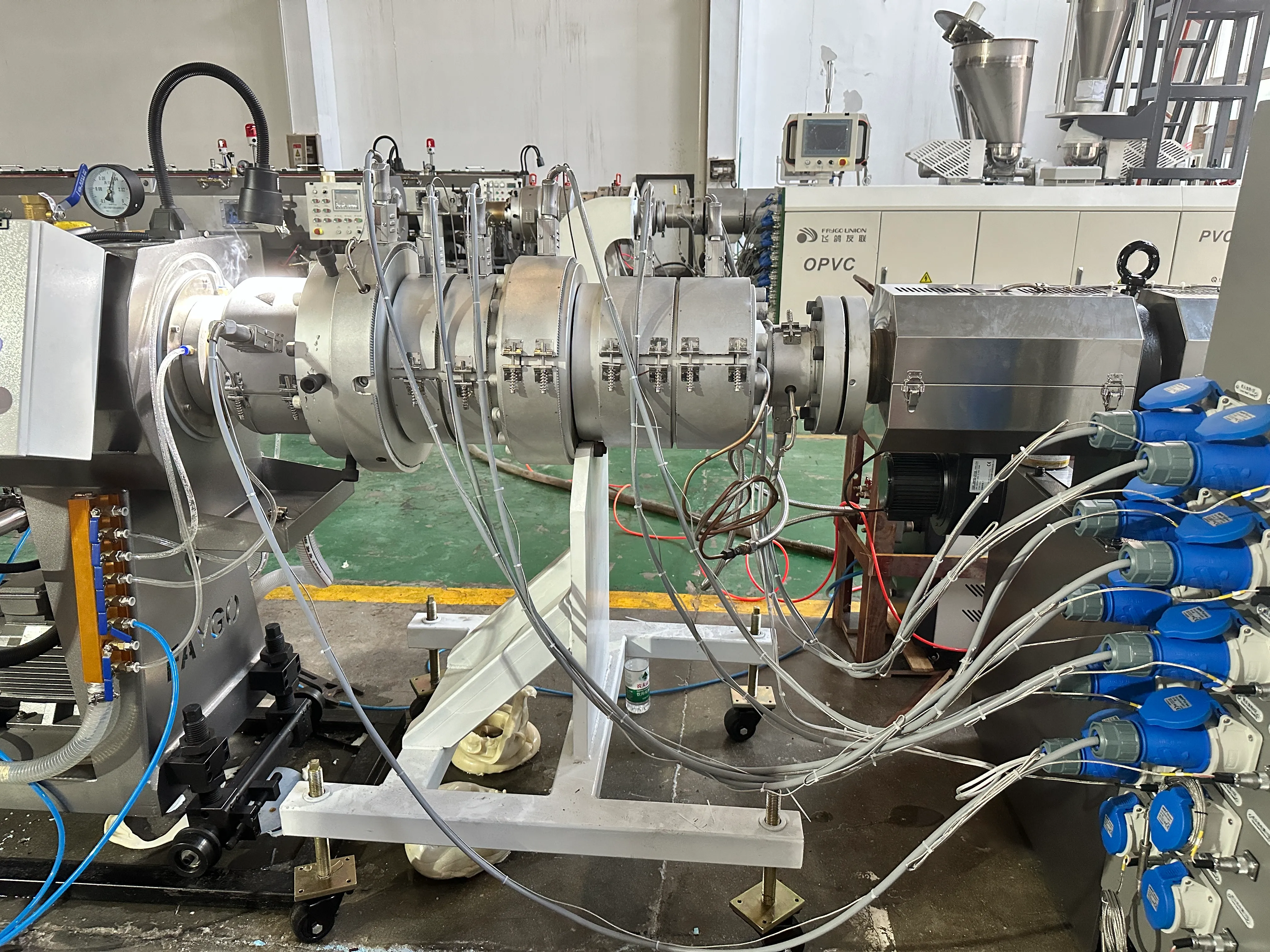

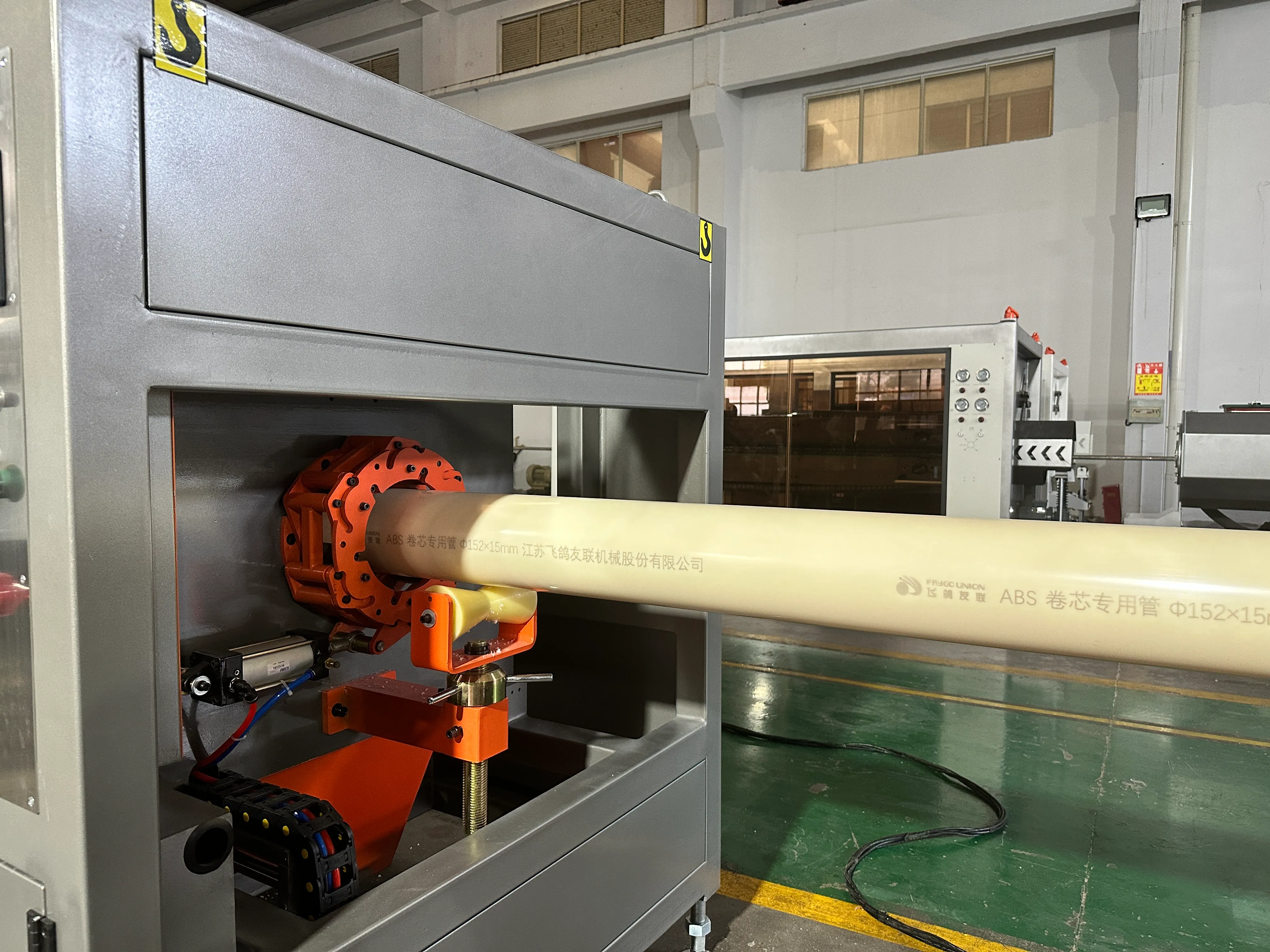

The ABS Pipe Production Line is designed for efficient and reliable extrusion of high-performance ABS pipes. It transforms premium virgin ABS raw materials into impact-resistant, corrosion-proof pipes ready for demanding applications. With its advanced technology, this line is ideal for production facilities requiring consistent, medium to high-volume output.

Technical parameter

| Model | SJZ-51 | SJZ-55 | SJZ-65 | SJZ-80 | SJZ-92 |

|---|---|---|---|---|---|

| Screw Diameter (mm) | 51/105 | 55/110 | 65/132 | 80/156 | 92/188 |

| Maximum Rotational Speed (rpm) | 40 | 38 | 38 | 37 | 36 |

| Main Motor (kW) | 18.5 | 22 | 37 | 55 | 90 |

| Capacity (kg/h) | 80~100 | 100~150 | 150~250 | 250~380 | 380~700 |

| Center Height (mm) | 1050 | 1050 | 1050 | 1050 | 1100 |

| Net Weight (kg) | 3000 | 3500 | 4000 | 5500 | 8000 |

| Length×Width×Height | 3.6*1.1*2.1 | 3.6*1.1*2.1 | 4.2*1.1*2.1 | 4.7*1.5*2.4 | 6*1.6*2.5 |

Key Features and Benefit

Premium materials and structure: Made from high-quality virgin ABS, with uniform wall thickness, offering impact resistance, corrosion resistance, flame retardancy, wear resistance, and strong pressure-bearing capacity.

Precision extrusion process: Wall thickness error far below international standards, robust structure effectively eliminating the risk of pipe bursting.

Excellent fluid performance: Smooth inner and outer walls, low friction and fluid resistance, extremely low friction coefficient, high flow rate, low energy consumption, and resistance to scaling with unobstructed flow.

Reliable connection design: Precise socket fitting with interference fit, enabling quick installation and excellent leak-proof sealing.

Primary Applications

Drain-Waste-Vent (DWV) Systems: Suitable for residential and commercial building drainage, waste, and ventilation pipes, offering reliable impact resistance and sealing.

Farmland Irrigation: Applied in agricultural irrigation systems, resistant to corrosion and suitable for outdoor exposure.

Chemical Plant Piping: Handles chemical media transport, leveraging ABS's corrosion and wear resistance.

Sewage Treatment Facilities: Used in wastewater discharge and treatment pipes for long-term durability and low maintenance.

Construction Site Conveyance: For temporary or permanent piping, withstanding on-site impacts and environmental stresses.

Large-Scale Breeding Farm Drainage: Supports livestock drainage systems, resisting corrosive substances.

Landscaping Irrigation: Ideal for garden and landscape piping, lightweight and weather-resistant for easy installation.

Industrial Fluid Transport: Suitable for general industrial pipelines, particularly in low-temperature or high-impact environments.

In summary, pipes produced by the ABS pipe production line serve as an upgraded alternative to PVC pipes, excelling in cold environments and high-impact applications, providing reliable sealing and long-term durability across construction, agriculture, chemical, and industrial sectors.