-

tel:

+86 133 9419 1191 -

email:

faygo2028@gmail.com

bottle labeling machine

bottle labeling machine

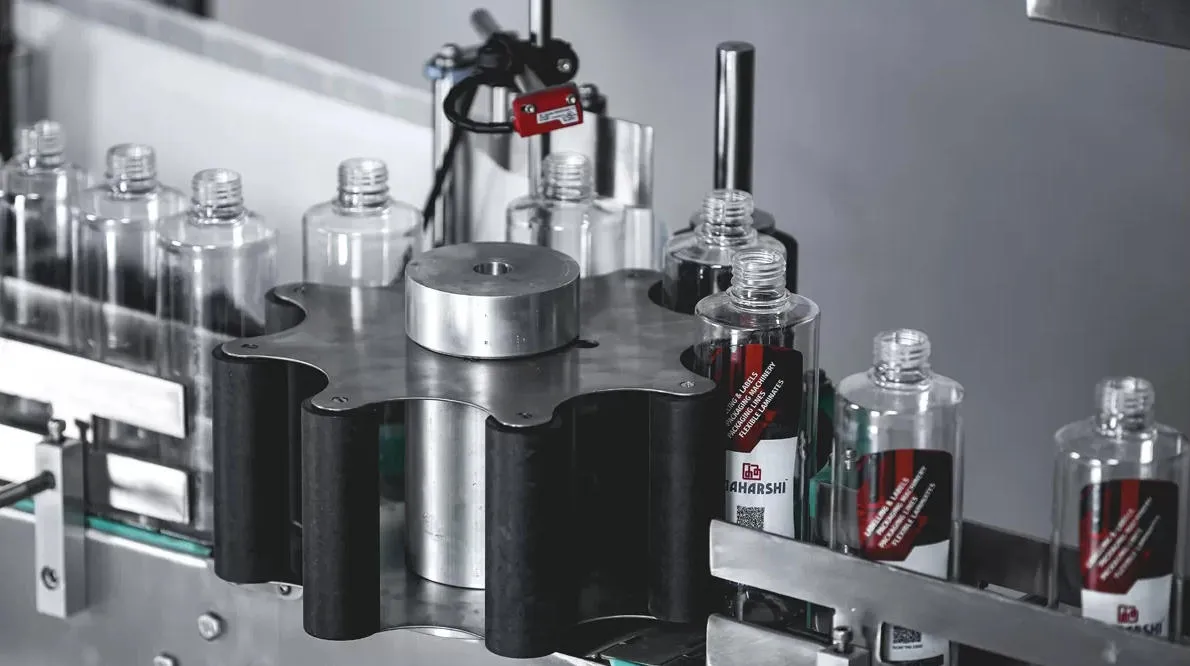

The bottle labeling machine is an essential piece of equipment for modern bottled water and beverage production lines. Its main purpose is to apply accurate and high-quality labels to PET bottles, glass bottles, or other container types. For many beverage brands, product labeling is not only a requirement for product identification, but also an important element of marketing and brand image. This machine provides fast, stable, and precise labeling to ensure every bottle looks clean, professional, and consistent on the shelf.

.webp?x-oss-process=image/resize,w_100/quality,q_100)

The bottle labeling machine is an essential piece of equipment for modern bottled water and beverage production lines. Its main purpose is to apply accurate and high-quality labels to PET bottles, glass bottles, or other container types. For many beverage brands, product labeling is not only a requirement for product identification, but also an important element of marketing and brand image. This machine provides fast, stable, and precise labeling to ensure every bottle looks clean, professional, and consistent on the shelf.

The bottle labeling machine is designed with advanced control systems and a reliable mechanical structure. It is capable of handling a wide range of bottle sizes and shapes used in the beverage industry. Using servo-driven mechanisms, it ensures smooth label feeding and positioning, minimizing label waste and reducing downtime. The machine can work with self-adhesive labels, shrink sleeve labels, wrap-around labels, or other label types depending on customer needs. Its high-speed labeling capability allows it to match the production speed of modern filling lines, making it suitable for both small and large-scale factories.

One of the key advantages of this machine is the stable labeling accuracy. The system detects each bottle as it enters the labeling zone and places the label at the exact position, even when bottles move at high speed. The touchscreen interface makes operation simple, allowing users to adjust labeling parameters easily. Changeovers between different bottle formats are quick, helping manufacturers save time and reduce labor costs.

Primary Applications

This bottle labeling machine is widely used in bottled water factories, juice plants, soft drink manufacturers, and other beverage production facilities. It can be integrated into new or existing production lines. Whether used for mineral water, flavored drinks, energy drinks, or carbonated beverages, the machine ensures a professional look that enhances brand visibility and consumer trust. It is ideal for factories seeking high efficiency, consistent labeling quality, and improved production management.

.webp?x-oss-process=image/resize)