-

tel:

+86 133 9419 1191 -

email:

faygo2028@gmail.com

Corrugated Pipe Production

Corrugated Pipe Production

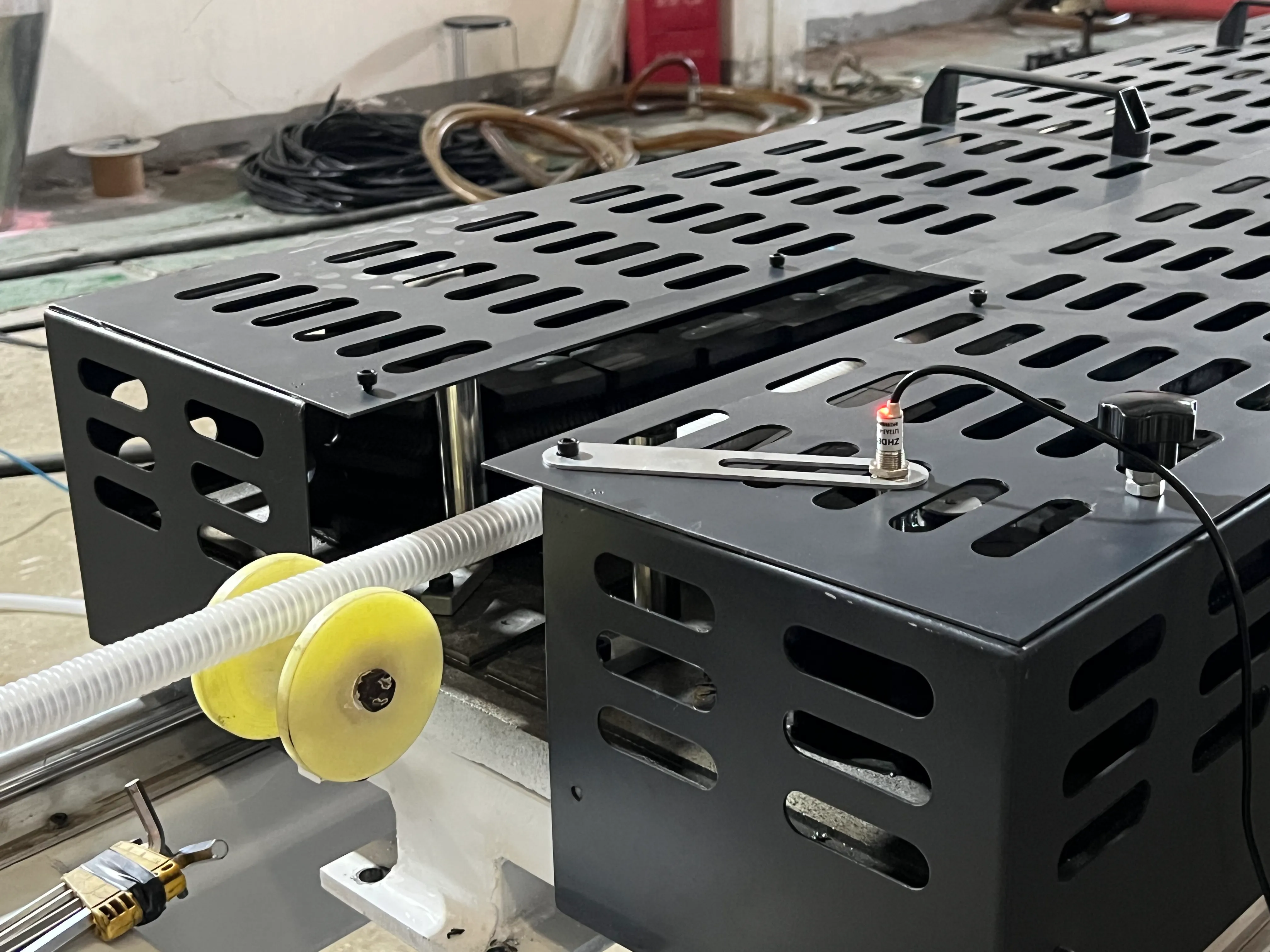

The Corrugated Pipe Production Line is designed for efficient and reliable extrusion of single-wall and double-wall plastic corrugated pipes. It transforms PE, PP, PVC, and similar raw materials into flexible, pressure-resistant pipes ready for diverse applications. With its advanced technology, this line is ideal for production facilities requiring consistent, medium to high-volume output.

.webp?x-oss-process=image/resize,w_100/quality,q_100)

Product introduction

|

Model |

SJ-30 |

SJ-45 |

SJ-65 |

|

Pipe diameter(mm) |

φ4.5-9 |

φ9-32 |

φ32-50 |

|

Screw L/D |

30:1 |

30:1 |

30:1 |

|

Capacity(kg/h) |

10 |

40 |

80 |

|

Motor Power(kw) |

4 |

11 |

18.5 |

|

Pair of modules |

38 |

42 |

52 |

|

Production Speed(m/min) |

6-10 |

8-12 |

8-15 |

Key Features and Benefit

High-speed forming system: Equipped with closed or horizontal corrugators using aluminum alloy modules and efficient water/air cooling, achieving rapid forming, uniform corrugations, and smooth walls while increasing production speed by 20–40%.

Dedicated extruder configuration: Single-screw for single-wall and twin/parallel twin-screw for double-wall pipes, supporting multiple materials like PE/PP/PVC with uniform plasticization, high output, and low energy consumption.

Vacuum forming technology: Integrates vacuum environments and modular molds for precise corrugation and high ring stiffness, enabling inline belling and quick mold changes across diameters.

Automated control and cooling: Features PLC touch-screen interfaces with online monitoring and auto-adjustment; multi-stage spray/water cooling significantly enhances efficiency and minimizes deformation.

Primary Applications

Cable and Wire Protection: For electrical, telecommunication conduits, and machine tool wiring, offering insulation and flexibility.

Drainage and Sewage Systems: In municipal stormwater, wastewater, and subsurface drainage, handling heavy loads with corrosion resistance.

Agricultural Irrigation: Applied in farmland drip/sprinkler systems and landscaping, lightweight and bendable for easy deployment.

Automotive and Appliances: As wire harness sheathing, air conditioner/washing machine drains, providing heat and impact resistance.

Inustrial Fluid Conveyance: For chemical lines, gas transmission, and industrial wastewater, suitable for low-pressure or gravity flow.

Construction and Infrastructure: In building ventilation, protective sleeving, and road drainage, ensuring longevity and simple installation.

In summary, pipes produced by the corrugated pipe production line are renowned for flexibility, lightness, and high strength, serving as ideal alternatives to rigid pipes across cable protection, drainage, and industrial conveyance sectors for efficient, cost-effective, and environmentally friendly solutions.

.webp)

.webp?x-oss-process=image/resize)