-

tel:

+86 133 9419 1191 -

email:

faygo2028@gmail.com

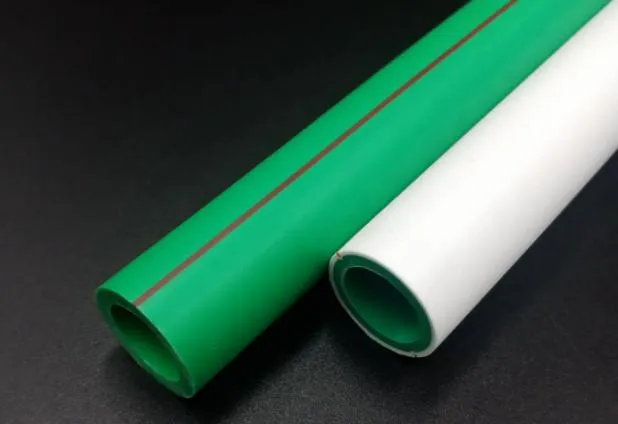

PPR Pipe Extrusion Line

PPR Pipe Extrusion Line

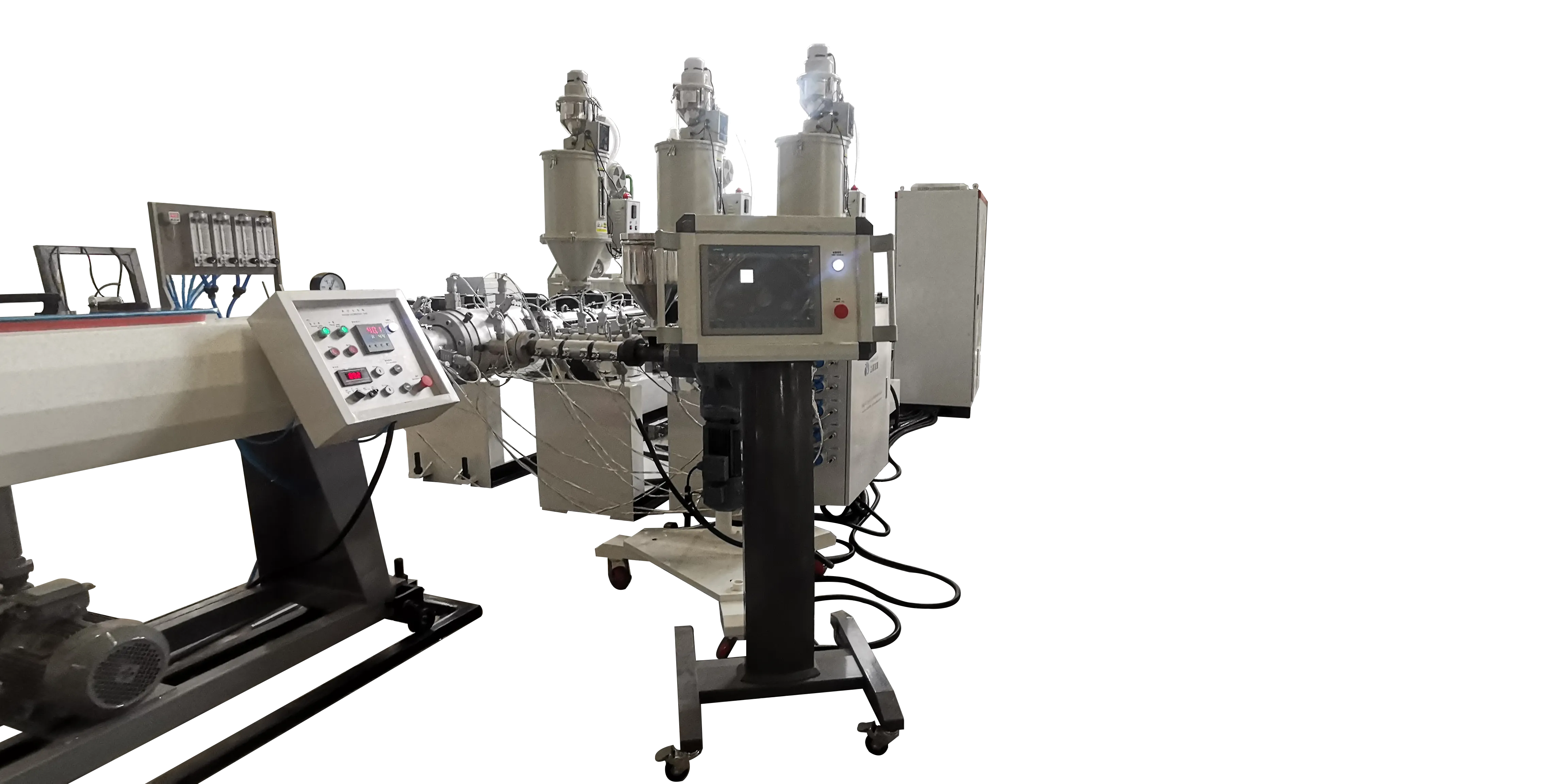

The PPR Pipe Extrusion Line is designed for efficient and reliable extrusion of polypropylene random copolymer (PPR) pipes. It transforms PPR raw materials into heat-resistant, pressure-bearing pipes ready for hot and cold water applications. With its advanced technology, this line is ideal for production facilities requiring consistent, medium to high-volume output.

Technical parameter

|

Model |

SJ65/30 |

SJ65/30 |

SJ75/30 |

|

Pipe diameter range(mm) |

φ16-63 |

φ20-110 |

φ50-160 |

|

Screw diameter(mm) |

65 |

65 |

75 |

|

L/D |

30:1 |

30:1 |

30:1 |

|

Motor power(kw) |

37 |

37 |

55 |

|

Drawing speed(m/min) |

0-10 |

0-8 |

0-8 |

|

Output(kg/h) |

40-80 |

60-120 |

80-160 |

|

Total length(m) |

25 |

25 |

28 |

Key Features and Benefit

Dedicated high-torque single-screw extrusion: L/D ratio exceeding 38:1 with barrier screw and efficient mixing heads ensures uniform plasticization and high melt strength for PPR, enabling high-speed extrusion (line speeds up to 35 m/min or more).

Spiral die design: Eliminates material stagnation, paired with disc-type calibration sleeves for smooth surfaces and uniform wall thickness, enhancing pressure resistance and thermal fusion properties in hot water pipes.

Multi-layer co-extrusion options: Supports aluminum-plastic composite (PPR-Al-PPR) or glass fiber reinforcement layers, improving thermal deformation resistance and oxygen barrier performance.

Precision cooling and haul-off systems: Multi-stage vacuum calibration and spray cooling with servo haul-off ensure dimensional stability and low internal stress, ideal for thin-wall high-speed production.

Automated intelligent control: PLC-integrated online wall thickness and diameter monitoring with auto-adjustment minimizes scrap and optimizes energy use, particularly for heat-fusion joint pipes.

These features distinguish the PPR line for high-speed, heat-resistant pipe production, offering superior high-temperature endurance (above 95°C), hygienic non-toxicity, and reliable heat-fusion connections while achieving high throughput and low material usage.

Primary Applications

Building Cold and Hot Water Supply: Prioritized for residential and commercial hot water piping, leveraging heat resistance and hygiene.

Underfloor Heating Systems: Suitable for radiant heating pipes, providing uniform heat distribution and thermal stability.

Potable Water Conveyance: For pure and drinking water networks, non-toxic and odorless meeting sanitary standards.

Air Conditioning and Ventilation Piping: Supports hot/cold water circulation systems with pressure tolerance and easy installation.

Industrial Hot Fluid Transport: For solar heaters and industrial thermal media lines, resisting high-temperature aging.

Compared to PE/HDPE lines, PPR pipes excel in indoor hot water and heating applications, serving as ideal alternatives to metal pipes with extended service life (over 50 years) and seamless heat-fusion joints.