-

tel:

+86 133 9419 1191 -

email:

faygo2028@gmail.com

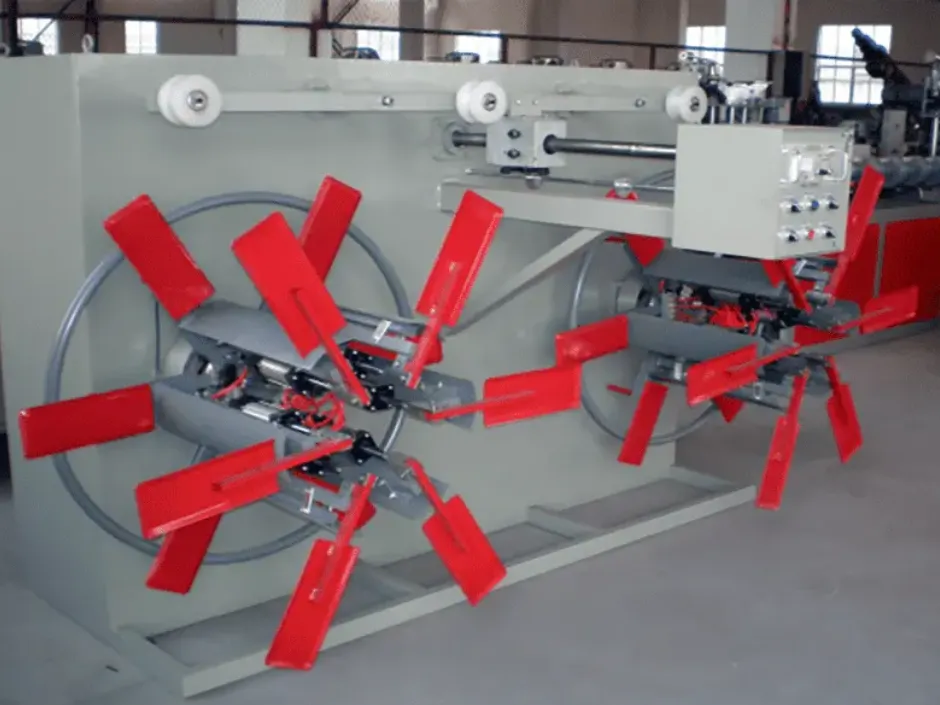

Winding machine

Winding machine

The Automatic Winding Machine For Plastic Pipe Profile is a high-efficiency auxiliary equipment specially designed for automatic winding of plastic pipes and profiles, typically integrated with complete production lines.

Technical parameter

| 1. | model: | SPS1200 | SPS1600 | SPS2200 | Belling-type |

| 2. | Winding diameter | 500-1000mm | 550-1500mm | 800-2000mm | Smooth-type |

| 3. | Winding speed | 0.5-40m/min | 0.5-40m/min | 0.5-40m/min | Smooth-type |

| 4. | Winding width | 300-500mm | 300-500mm | 300-500mm | R-type Smooth-type |

| 5. | Winding pipe diameter scope | Q16-40mm | Ø16-63mm | Q63-110mm | R-type Smooth-type |

| 6. | Air pressure | 0.6mpa | 0.6mpa | 0.6mpa | R-type Smooth-type |

| 7. | Torque motor | 10N.M | 10N.M,25N.M | 25N.Mx2 | R-type Smooth-type |

| 8. | Dimension(mm) | 2800×1700×1800 | 3000×2800×2000 | 3000×3200×2000 | R-type Smooth-type |

| 9. | Weight | 1000kg | 1500kg | 2000kg | R-type Smooth-type |

Key Features and Benefit

High Automation: Fully automatic operation with PLC or touch-screen controls, synchronized with extrusion lines for precise tension and speed adjustment.

Torque Motor Drive: Equipped with torque motors to maintain uniform winding tension and prevent pipe deformation.

Pipe Arranging System: Dedicated traversing device ensures neat and orderly pipe layering.

Single/Double Disk Options: Available in single or double disk configurations; double disks enable alternating operation to minimize downtime.

Adjustable Parameters: Supports various pipe diameters with quick changeovers.

Enhanced Efficiency: Automates coiling to increase overall line productivity and reduce manual labor.

Superior Coil Quality: Consistent tension and arrangement produce uniform, damage-free coils.

Primary Applications

Automatic winding machines are primarily used in the downstream coiling process of plastic pipe extrusion lines, suitable for PE, PP, PVC, corrugated, aluminum-plastic composite, PERT heating, and drip irrigation pipes. They are widely applied in municipal water supply/drainage, gas transmission, agricultural drip and sprinkler irrigation systems, cable/optical fiber protection, building plumbing and heating, industrial fluid conveyance, landscaping irrigation, and HVAC (heating, ventilation, and air conditioning) systems, ensuring efficient packaging, storage, and transportation.