-

tel:

+86 133 9419 1191 -

email:

faygo2028@gmail.com

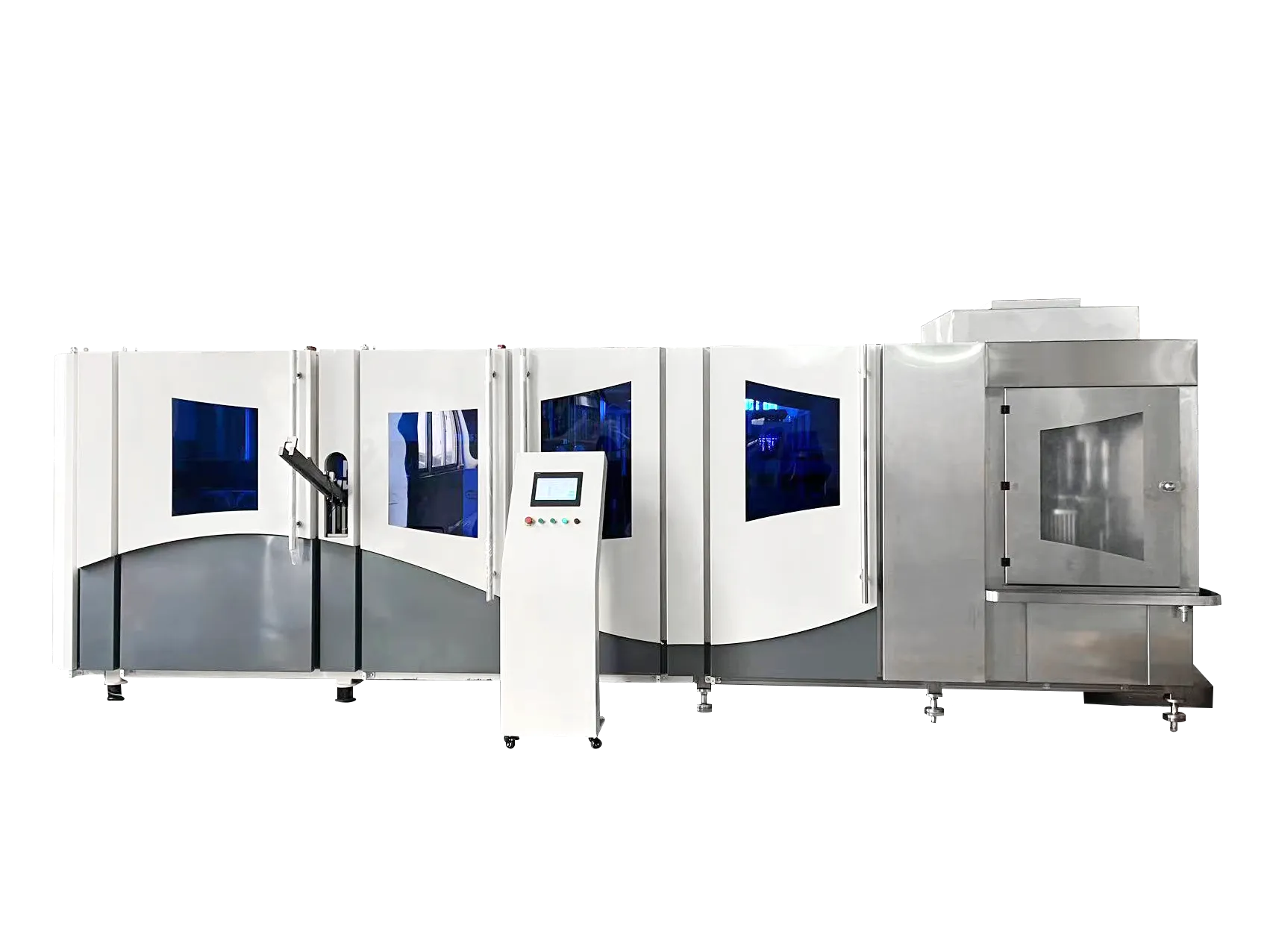

linear blowing-filling-capping machine

linear blowing-filling-capping machine

The Faygo Union Linear Blowing-Filling-Capping Machine represents a significant advancement in integrated bottling technology. This combiblock system seamlessly combines blowing, filling, and capping processes into a single, streamlined unit, designed to enhance production efficiency, ensure product hygiene, and reduce operational costs. Ideal for small to medium-scale production plants, this machine is engineered to handle a variety of liquid products, including mineral water, beverages, juices, and oils .

.webp?x-oss-process=image/resize,w_100/quality,q_100)

.webp?x-oss-process=image/resize,w_100/quality,q_100)

.webp?x-oss-process=image/resize,w_100/quality,q_100)

.webp?x-oss-process=image/resize,w_100/quality,q_100)

.webp?x-oss-process=image/resize,w_100/quality,q_100)

.webp?x-oss-process=image/resize,w_100/quality,q_100)

.webp?x-oss-process=image/resize,w_100/quality,q_100)

.webp?x-oss-process=image/resize,w_100/quality,q_100)

.webp?x-oss-process=image/resize,w_100/quality,q_100)

.webp?x-oss-process=image/resize,w_100/quality,q_100)

Technical parameter

| Technical deatils for Series CGX Linear type Blowing-filling-capping Machine: | ||||

| Model No. | CGX6-16-8 | CGXX6-18-8 | CGXX8-24-10 | |

| Cavity qty. | 6 | 6 | 8 | |

| Filling valve qty. | 16 | 18 | 24 | |

| Capping head qty. | 8 | 8 | 10 | |

| Bottle specifications | Max. Bottle volume (ml) | 2000 | 2000 | 750 |

| Max. Bottle height (mm) | 328 | 328 | 300 | |

| Preform specifications | Max. Bottle body diameter (mm) | 105 | 105 | 75 |

| Bottle neck inner diameter (mm) | 20–25 | 20–25 | 20–25 | |

| Max. Preform length (mm) | 150 | 150 | 140 | |

| Output (500ml,17g bottle for example) | 10,000-11,000 | 12,000-13,000 | 15,000-16,000 | |

Key Features and Benefit

1. Compact Linear Design and High Efficiency

The machine features a space-saving linear layout, with some models occupying as little as 7 meters in length and 1.6 meters in width . This compact footprint is perfect for facilities with limited space. Despite its modest size, it delivers impressive output, with capacities ranging from 10,000 to 20,000 bottles per hour (BPH), adaptable to bottle volumes from 250ml to 2000ml .

2. Advanced Control and Operation

Equipped with a user-friendly touch screen interface, the machine allows for easy operation and monitoring . The core control system is powered by a Programmable Logic Controller (PLC), ensuring precise and stable operation. Key components from reputable brands like Siemens or Mitsubishi contribute to the machine's reliability and high processing precision .

3. Energy and Resource Efficient

The linear design is not only compact but also contributes to lower consumption of water and electricity, making it a cost-effective and environmentally conscious choice for bottlers .

Designed with product safety as a priority, the machine incorporates features that significantly improve sanitary conditions. It utilizes mechanical neck-handling for bottles and a closed production zone to minimize the risk of contamination during the process . Furthermore, the direct connection technology between the air conveyor and the in-feeding star-wheel eliminates the need for screws and additional conveyors, simplifying the process and reducing potential contamination points .

Primary Applications

The versatility of the Faygo Union Linear Machine makes it suitable for a wide range of applications in the liquid packaging industry. It is an ideal solution for:

- Bottled Water Plants: Efficiently produces bottles for mineral and pure drinking water .

- Beverage Industry: Capable of handling non-carbonated liquids such as juices and teas .

- Edible Oil and Other Liquids: The technology is also adaptable for filling edible oils and other non-carbonated liquid products .

.webp?x-oss-process=image/resize)

.webp?x-oss-process=image/resize)

.webp?x-oss-process=image/resize)

.webp?x-oss-process=image/resize)

.webp?x-oss-process=image/resize)

.webp?x-oss-process=image/resize)

.webp?x-oss-process=image/resize)

.webp?x-oss-process=image/resize)

.webp?x-oss-process=image/resize)

.webp?x-oss-process=image/resize)

.webp)