-

tel:

+86 133 9419 1191 -

email:

faygo2028@gmail.com

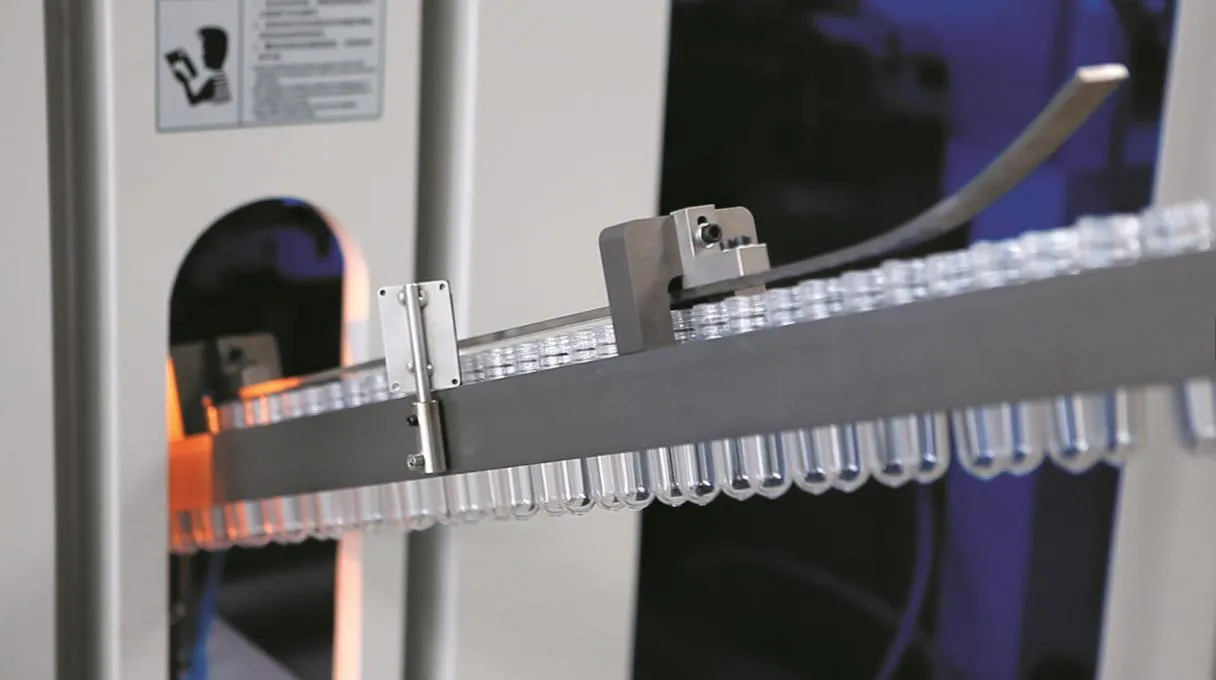

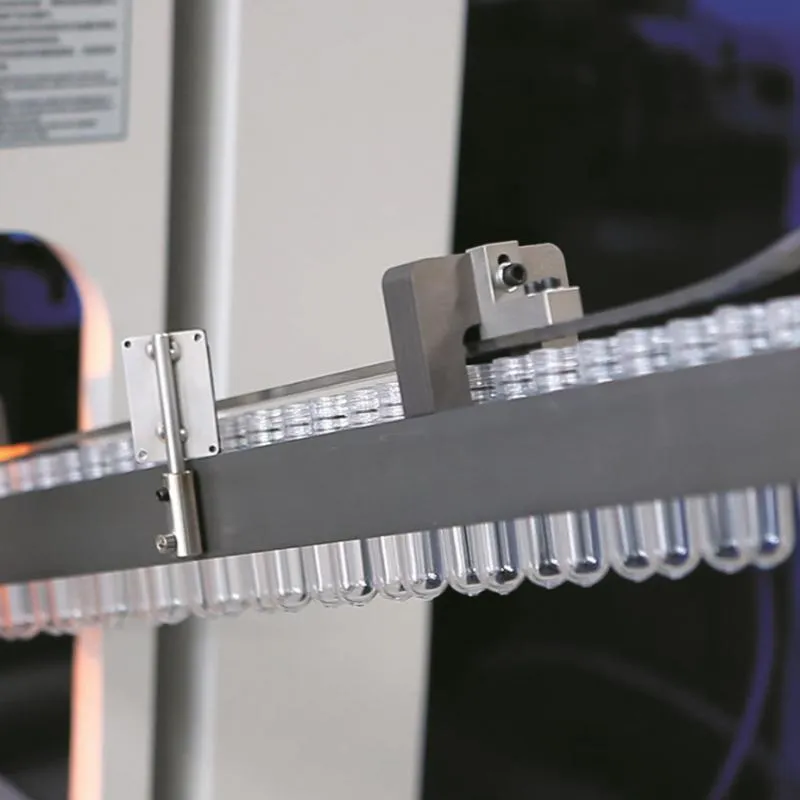

Automatic Linear High-speed PET Bottle Blowing Machine

Automatic Linear High-speed PET Bottle Blowing Machine

Our Linear High-Speed PET Bottle Blowing Machine is designed for efficient and reliable production of high-quality PET bottles. It transforms PET preforms into finished bottles ready for filling. With its advanced technology, this machine is perfect for bottling plants that require consistent, medium to high-volume output.

.webp?x-oss-process=image/resize,w_100/quality,q_100)

Technical parameter

| Model | FG4 | FGX4 | FG6 | FGX6 | FG8 | FGX8 |

| Cavity number cav | 4 | 4 | 6 | 6 | 8 | 8 |

| Operation speed BPH | 6500-8000 | 8000-9000 | 9000-10000 | 9000-13000 | 12000-13000 | 15000-16000 |

| Max volume ml | 2000 | 2000 | 2000 | 2000 | 750 | 750 |

| Suitable inner bottle neck mm | 20-25 | 20--25 | 20-25 | 20-38 | 20-25 | 20-25 |

| operation power kw | 25 | 28 | 30 | 35 | 45 | 45 |

| Total installation power kw | 51 | 58 | 51 | 97 | 97 | 97 |

| Air consumption min/30bar | 4 | 4 | 6 | 6.5 | 8 | 8 |

| Machine dimension(L*W*H) m | 3.8X1.3X2.3 | 3.8X1.3X2.3 | 4.6X1.3X2.3 | 5.2X1.3X2.5 | 5.2X1.3X2.5 | 5.2X1.3X2.5 |

| Machine weight Kg | 3500 | 3800 | 4500 | 5500 | 5000 | 5000 |

Key Features and Benefits

- All-Servo Electric Drive for Energy Savings: This machine uses a fully servo-driven motor system. It is incredibly energy-efficient. Our unique variable-pitch transmission design reduces energy consumption by over 40% compared to traditional blowers. This significantly lowers your operating costs and supports your sustainability goals.

- Linear Design for Stable High-Speed Production: The linear layout allows for a smooth and continuous workflow. Preforms move in a straight line through each station: heating, blowing, and ejection. This simple and robust design ensures high-speed operation with minimal vibration and maximum stability.

- Optimized for Medium-High Output: This machine delivers powerful production capacity. It is capable of producing up to 16,000 bottles per hour (for a 500ml bottle). This makes it an ideal solution for production lines that need a strong and dependable output rate.

- Wide Bottle Size Versatility: The machine offers great flexibility. It can produce a wide range of bottle sizes, from 250ml to 2.0 liters. Quick mold changeovers allow you to switch between different bottle designs and capacities with minimal downtime.

- Precision and Consistent Quality: Each servo motor ensures precise control over the entire process. This results in excellent bottle quality with consistent wall thickness, high clarity, and superior strength for every single bottle.

Primary Applications

This linear blow molder is ideal for creating clear and strong PET bottles for various industries, including:

1. Bottled Water: Producing still and purified water bottles.

3. Edible Oils: Creating safe and clean containers for cooking oil.

.webp?x-oss-process=image/resize)

.webp?x-oss-process=image/resize,w_100/quality,q_100)

.webp?x-oss-process=image/resize,w_100/quality,q_100)