-

tel:

+86 133 9419 1191 -

email:

faygo2028@gmail.com

Semi-Automatic PET Blow Molding Machine

Semi-Automatic PET Blow Molding Machine

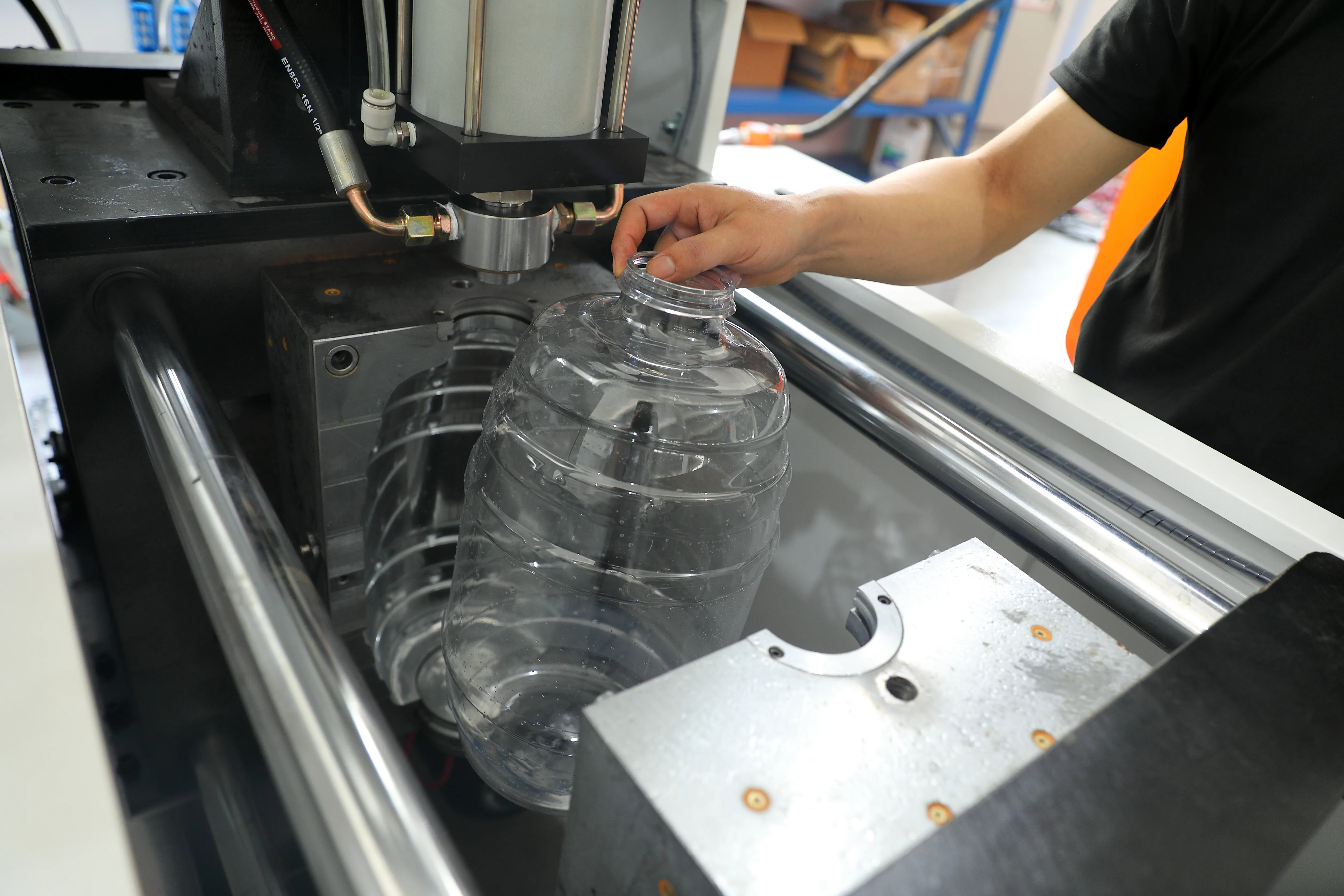

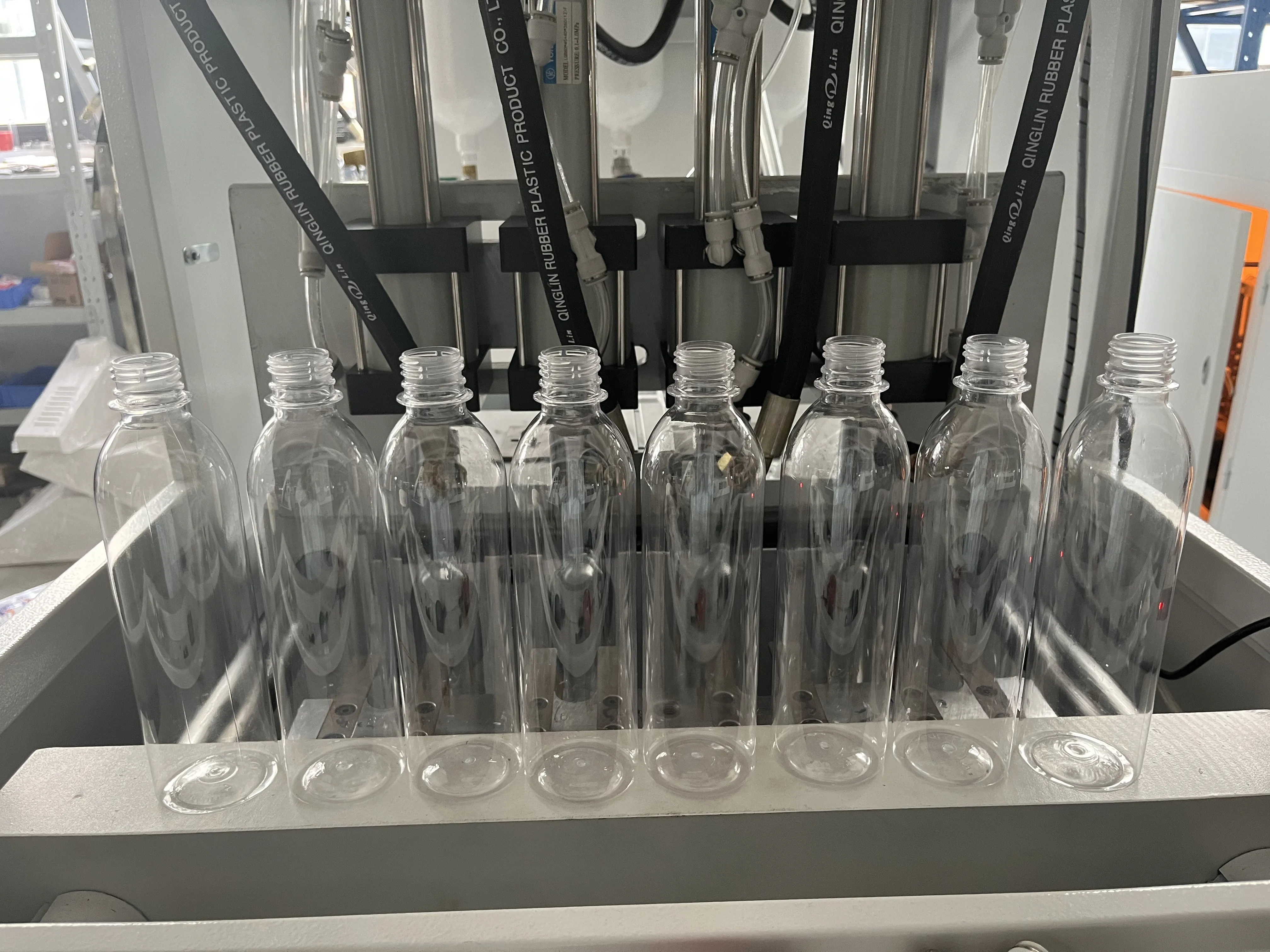

This Semi-Automatic PET Bottle Blowing Machine is the ideal and cost-effective solution for startups, small businesses, and laboratories. This compact machine is designed for low-volume production and custom bottle manufacturing. It offers maximum flexibility for producing a wide range of bottle sizes without a large investment.

.webp?x-oss-process=image/resize,w_100/quality,q_100)

.webp?x-oss-process=image/resize,w_100/quality,q_100)

.webp?x-oss-process=image/resize,w_100/quality,q_100)

.webp?x-oss-process=image/resize,w_100/quality,q_100)

- Compact and Affordable: This machine has a very small footprint, saving valuable floor space in your workshop or facility. Its simple design makes it a highly affordable entry point into bottle production, offering a great return on investment for small-scale operations.

- Unmatched Flexibility and Manual Operation: The process requires an operator to manually place a preform into the machine and remove the finished bottle. This hands-on approach allows for direct quality control and makes the machine incredibly versatile. It is perfect for producing small batches, prototyping new bottle designs, and special orders.

- Wide Range of Bottle Sizes: Despite its small size, this machine is remarkably powerful and versatile. It can produce an extremely wide range of bottle sizes, from small 250ml bottles up to large 25-liter containers. This makes it suitable for a vast array of products.

- Simple Operation and Low Maintenance: The machine is very easy to use and requires minimal training. Its straightforward mechanical design also means lower maintenance costs and easier servicing, ensuring reliability and long machine life.

- Ideal for Prototyping and Custom Orders: It is the perfect tool for research and development. You can quickly test and produce prototype bottles before committing to large-scale production. It is also excellent for fulfilling custom or personalized bottle orders that are not feasible on high-speed automatic lines.

Primary Applications

This semi-automatic blower is perfect for:

1. Startups & Small Businesses: Producing bottles for small-batch beverages, homemade sauces, craft oils, or honey.

2. Laboratories & R&D Centers: Developing and testing new bottle designs and materials.

3. Customized and Promotional Products: Creating unique bottles for special events, weddings, or corporate gifts.

4. Large Container Manufacturing: Producing big 5-gallon (19L) or 25L water bottles and industrial containers.

.webp?x-oss-process=image/resize)

.webp?x-oss-process=image/resize)

.webp?x-oss-process=image/resize)

.webp?x-oss-process=image/resize)

.webp?x-oss-process=image/resize,w_100/quality,q_100)

.webp?x-oss-process=image/resize,w_100/quality,q_100)